Machine Vision

Productive manufacturing processes must be flexible. Lot sizes are becoming smaller, clock speeds faster and quality demands ever higher. As a result, conventional inspection processes are reaching their limitations. This is not the case for industrial image processing systems. Thanks to their enormous potential, they have increasingly developed into the standard discipline for automation technology – especially since intelligent image processing systems have made their application easier. We offer you a wide range for all application areas – from systems for application-specific image processing up to general purpose systems for universal use.

According to its strategy, Provendor invests in machine vision systems.

Familiarize yourself with the technology and ask for a bid!

APPLICATIONS FOR MACHINE VISION

The main reasons for the rapid growth in the use of machine vision in industry today, are in the possibilities it’s offering. It’s being implemented on many different applications on different areas of industry, for example: object- & motion recognition, measurement, inspection, assembly and control-tasks.

Electronics-industry

As component-sizes are getting smaller and production lines ever faster, demands for accuracy and automated quality control must be met. The electronics-industry uses machine vision for measurement, inspection and assembly-tasks.

- PCB’s

- Components

- Housing-cases

- Packaging

Brewing, food & beverage industry

As demands for foodstuff quality and increased production-line speed grow, the need for fast quality inspection arises. Materials are sorted by size, quality and color using machine vision. The final product and packaging is inspected with machine vision before it’s delivered to the grocers shelf.

- Sorting of potatoes based on size and analysis of surface defects.

- Measurement of fat-content in spare-ribs

- Sorting of vegetables, fruit and berries based on size and color.

- Quality inspection of bottles and other packaging

Pharmaceutical industry

The demand for quality in products of the pharmaceutical industry is extremely high. To assure this quality, materials and final products undergo inspections with the latest technology. Machine vision fits in well when it comes to pharmaceutical quality control.

- Inspection of quality and product codes of packaging

- Sorting and quality control of medicines

- Manufacturing of medical instruments

Textile industry

- Color analysis of fabrics and strings

- Quality control of final products

- Measurement of fabrics

Machine industry

- Measurement and analysis of engine-parts and engines

- Quality control

- Assembly (placement & motion control)

Sawmill industry

- Quality inspections of sawn wood: recognition of knots,

- holes and cracks, measurement of dimensions.

- Products of the paper-industry

- Motion control

Rubber and Plastic industries

- Measurement and quality control of rubber and plastic products.

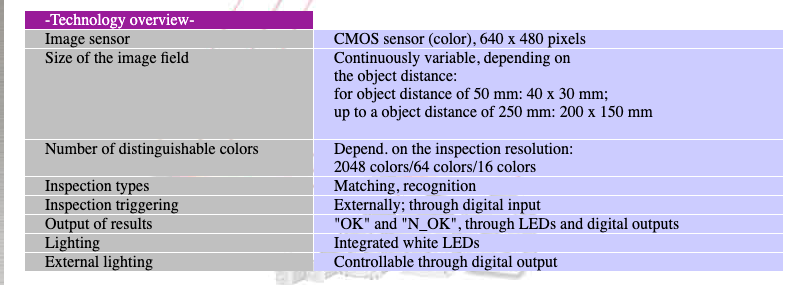

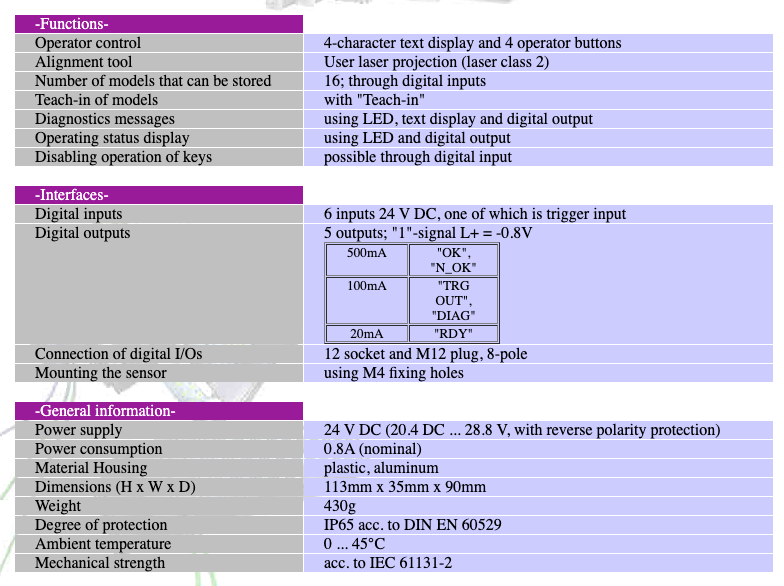

SIEMENS SIMATIC MV220

-COMPACT COLOR AREA SENSORS

The compact color area sensor SIMATIC MV220 is a complete image processing system for the automatic inspection of color objects. The MV220 is designed for applications in industrial manufacturing, packaging applications and food & beverage industry.